Staggered extrusion type light steel keel low-position cement grouting equipment

A light steel keel and cement grouting technology, applied in the field of light steel keel, can solve the problems of increased workload, casualties, artificial falls, etc., and achieve the effect of avoiding waste and uniform coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

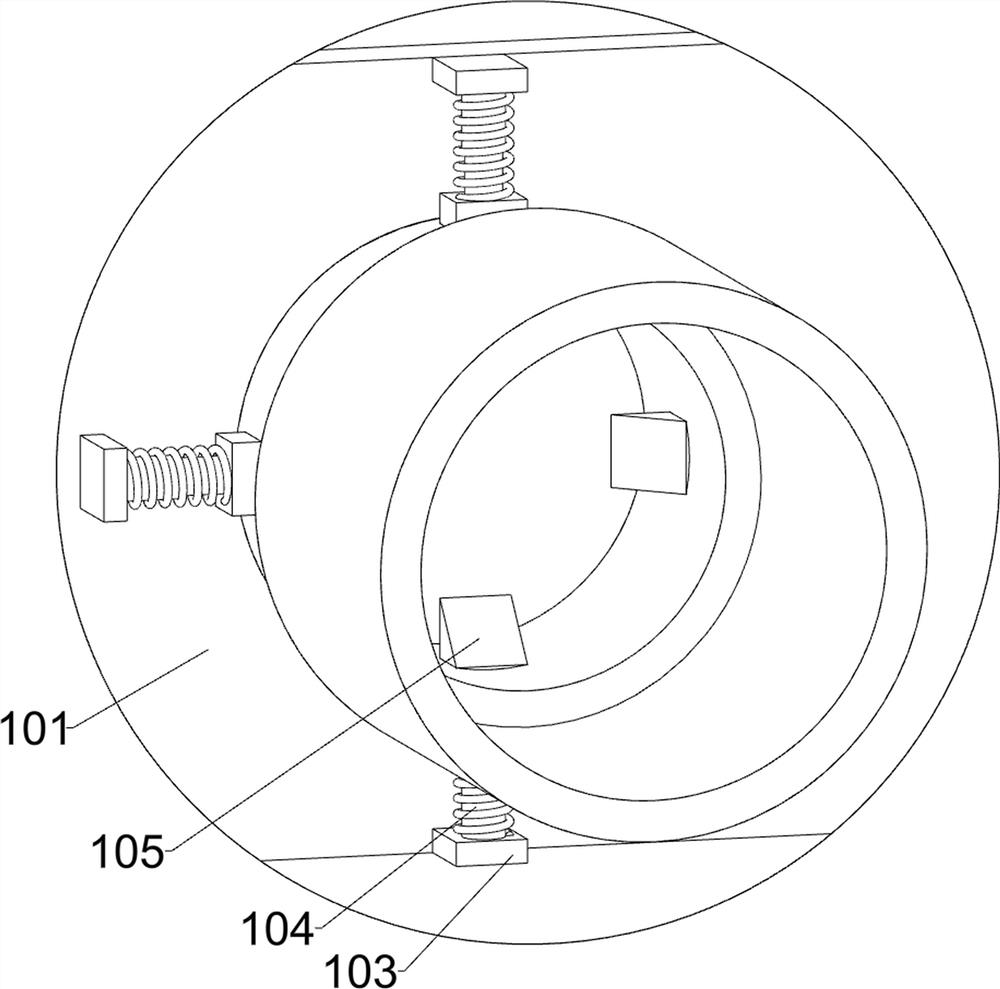

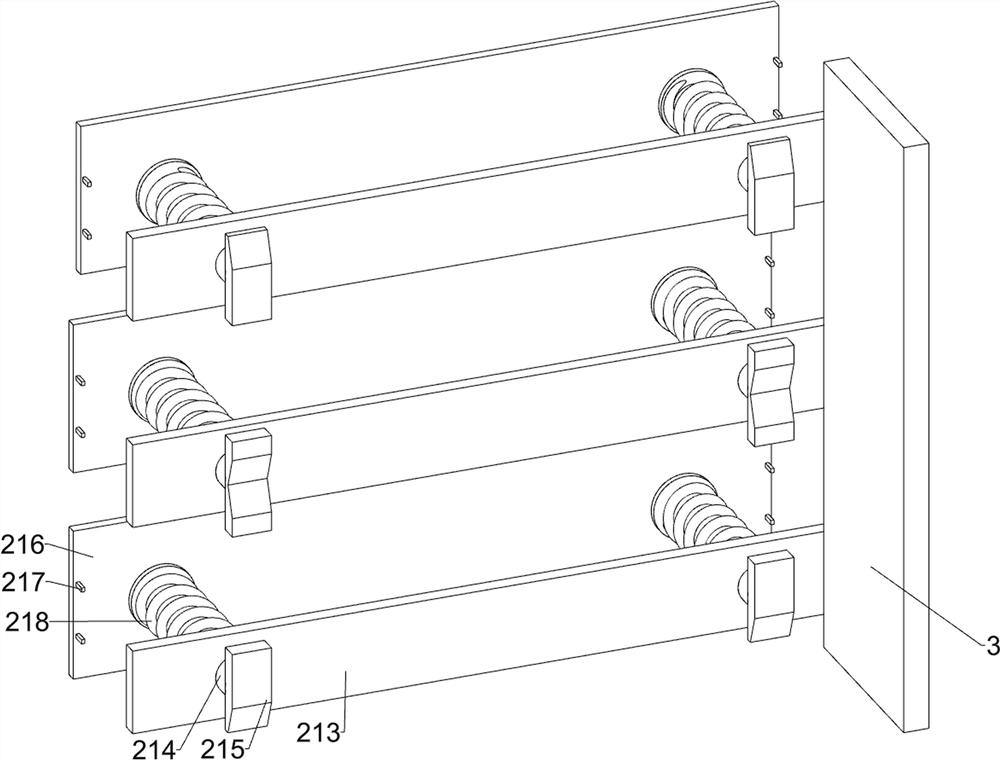

[0036] A dislocation extrusion type cement grouting equipment at the lower part of the light steel keel, such as Figure 1-13 As shown, it includes base plate 1, casters 2, housing 3, handle 4, barrier system, laminating system and slurry screed system; four corners of the lower side of base plate 1 are connected with casters 2; the upper side of base plate 1 is connected with shell Body 3; a handle 4 is connected to the middle part on the left side of the casing 3; a barrier system is arranged above the casing 3; a fitting system is connected inside the casing 3; three slurry screed systems distributed up and down are connected to the fitting system ; The three slurry screed systems have the same structure.

[0037] Working process: When using this misplaced extruded light steel keel low cement grouting equipment, the operator first connects the barrier system bolts between the two vertical keels of the light steel keel wall, and then places the plate on the barrier system T...

Embodiment 2

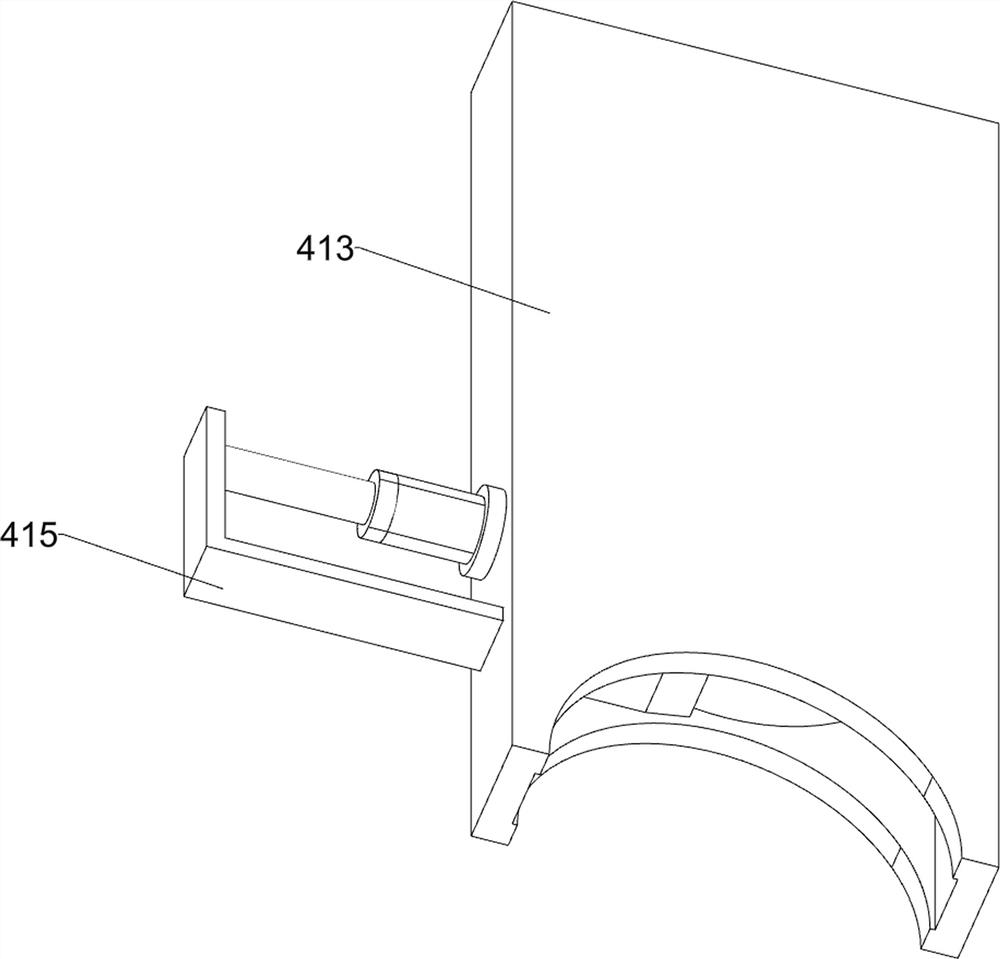

[0052] On the basis of Example 1, such as figure 1 and Figure 14-16 As shown, it also includes a snapping system; the upper side of the housing 3 is connected with the snapping system; the snapping system is located in front of the barrier system; the snapping system includes a fixed seat 401, an electric slide rail 402, an electric slider 403, a second Four connecting plates 404, electric push rod 405, second disk 406, fifth connecting plate 407, third L-shaped plate 408, second circular tube 409, bracket 410, fourth elastic column 411, third wedge-shaped block 412, Storage box 413, small push rod 414 and fourth L-shaped plate 415; housing 3 upper side is fixedly connected with fixed base 401; fixed base 401 upper side bolt is connected with electric slide rail 402; electric slide rail 402 is slidingly connected with electric The slider 403; the upper side of the electric slider 403 is fixedly connected with the fourth connecting plate 404; the bolt on the upper rear side o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap